The Brewing Process

Commercial Quality Beer at Half the Price!!

Growler Club

The next Growler Club beer will be the Filipino Dark, Al's take on the San Miguel Dark Lager on the 14th of November.

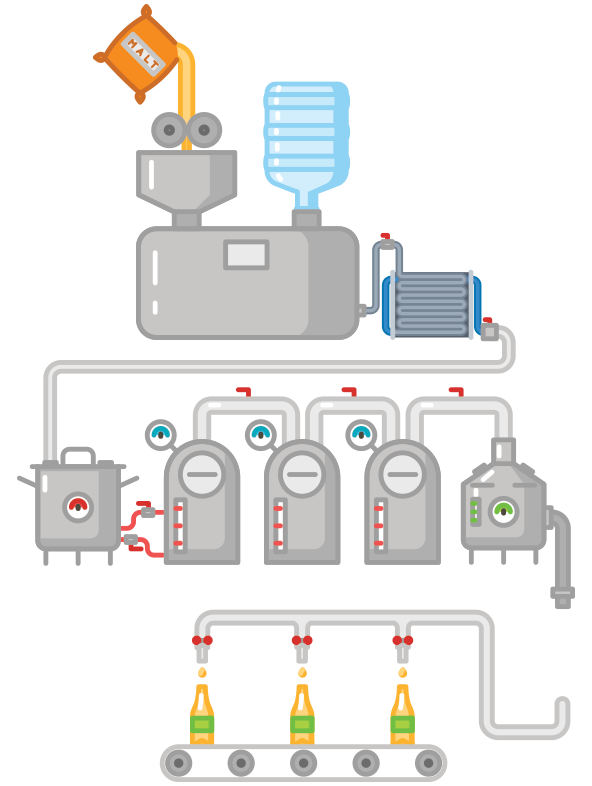

How does micro-brewing with Brew Factory work?

Choose your favourite beer style

Brew Factory has over 150 quality beer recipes to choose from.

Many of these are styled after some very popular and exotic commercial brews such as Heineken, Guinness and Corona. Others are original recipes which have been designed drawing from many years of experience in the beer business and working with our customers to create specific characteristics.

Any of our recipes can be modified to suit the individual tastes or with our expert help you can even use your own ideas to 'invent' your own custom beer.

Making your brew

Following the simple instructions on your recipe sheet, you measure the malts, grains and hops into their respective containers.

These ingredients are then added ( with the help of our excellent staff ) at various times throughout the brewing process. At the completion of the brewing ( about 1 hour ) your 'WORT' is transfered from the kettle to the fermenter via a hop filter and heat exchanger. The temperature of the 'WORT' is reduced during this transfer to allow the yeast to be added at the correct temperature to ensure the perfect fermenting environment is achieved. Your brew is then placed in the Fermentation room and you need to book your return 'Bottling', 'Canning' or Kegging time. ( minimum two weeks from brewing date )

Fermentation

Fermenting your beer at the correct temperature and in the correct environment is crucial to the production of a quality beer.

Brew Factory uses purpose built temperature controlled fermenting rooms and established testing and sanitation procedures to ensure your beer is perfect every time. After the fermentation is complete, usually within 10 days, your beer is placed into a cold room and allowed to settle, mature and wait patiently for your return. Your beer is then filtered, transferred into stainless steel carbonating kegs and carbonated the morning you are booked to return.

Canning, Bottling or Kegging

At your appointed time, you return to the Brew Factory to transfer your finished beer into whatever packaging you wish.

You have the option of Canning, Kegging or bottling ( using your own bottles or purchasing from us ). If using your own bottles please ensure they are as clean as possible BEFORE returning to save you time.

Each brew yields 50 litres of beer ( 133 x 375ml ) ( 151 x 330ml ) ( 145 345ml or an even 100 x 500ml Brew Factory cans.

Your bottles are then placed on our own sanitiser and rinsed ready for use.

This is the very best part!!! After checking to ensure quality you simply use our very own Canning equipment or individually refrigerated bottling stations and fill your preferred packages with your premium Brew Factory beer. It could not be easier than that!!

Many of our brewers find that they 'SPILL' so much beer during bottling they have to arrange a taxi to get home.

Storage

After you get your beer home from Brew Factory, it needs to be kept cold in a fridge to avoid any re-fermentation should any yeast get through the filtration system. Because at Brew Factory, we do not add any chemicals or preservatives to guard against re-fermentation. This is a safe guard to protect your beer.

Drinking

Brew Factory has found that very few of our customers require any assistance in this area of their Micro-Brewing experience.

However, as an important part of Brew Factory's quality service, our policy is to offer our expertise and skills to any and all of our valued customers who may require guidance.

PLEASE let us know if we can HELP!!!

Step 1: Choose your favourite beer style

Brew Factory has over 150 quality beer recipes to choose from.

Many of these are styled after some very popular and exotic commercial brews such as Heineken, Guinness and Corona. Others are original recipes which have been designed drawing from many years of experience in the beer business and working with our customers to create specific characteristics.

Any of our recipes can be modified to suit the individual tastes or with our expert help you can even use your own ideas to ‘invent’ your own custom beer.

Step 2: Making your brew

Following the simple instructions on your recipe sheet, you measure the malts, grains and hops into their respective containers.

These ingredients are then added ( with the help of our excellent staff ) at various times throughout the brewing process. At the completion of the brewing ( about 1 hour ) your ‘WORT’ is transfered from the kettle to the fermenter via a hop filter and heat exchanger. The temperature of the ‘WORT’ is reduced during this transfer to allow the yeast to be added at the correct temperature to ensure the perfect fermenting environment is achieved. Your brew is then placed in the Fermentation room and you need to book your return ‘Bottling’, ‘Canning’ or Kegging time. ( minimum two weeks from brewing date )

Step 3: Fermentation

Fermenting your beer at the correct temperature and in the correct environment is crucial to the production of a quality beer.

Brew Factory uses purpose built temperature controlled fermenting rooms and established testing and sanitation procedures to ensure your beer is perfect every time. After the fermentation is complete, usually within 10 days, your beer is placed into a cold room and allowed to settle, mature and wait patiently for your return. Your beer is then filtered, transferred into stainless steel carbonating kegs and carbonated the morning you are booked to return.

Step 4: Canning, Bottling or Kegging

At your appointed time, you return to the Brew Factory to transfer your finished beer into whatever packaging you wish.

You have the option of Canning, Kegging or bottling ( using your own bottles or purchasing from us ). If using your own bottles please ensure they are as clean as possible BEFORE returning to save you time.

Each brew yields 50 litres of beer ( 133 x 375ml ) ( 151 x 330ml ) ( 145 345ml or an even 100 x 500ml Brew Factory cans.

Your bottles are then placed on our own sanitiser and rinsed ready for use.

This is the very best part!!! After checking to ensure quality you simply use our very own Canning equipment or individually refrigerated bottling stations and fill your preferred packages with your premium Brew Factory beer. It could not be easier than that!!

Many of our brewers find that they ‘SPILL’ so much beer during bottling they have to arrange a taxi to get home.

Step 5: Storage

After you get your beer home from Brew Factory, it needs to be kept cold in a fridge to avoid any re-fermentation should any yeast get through the filtration system. Because at Brew Factory, we do not add any chemicals or preservatives to guard against re-fermentation. This is a safe guard to protect your beer.

Step 6: Drinking

Brew Factory has found that very few of our customers require any assistance in this area of their Micro-Brewing experience.

However, as an important part of Brew Factory’s quality service, our policy is to offer our expertise and skills to any and all of our valued customers who may require guidance.

PLEASE let us know if we can HELP!!!